Top this!

I’m working on a 19th century Longcase (Grandfather) clock. Everything was pretty straight forward in my restoration including and inspection and of the escape wheel and anchor. The escape wheel is the gear that has just enough power to allow the pendulum, with it’s associated anchor, to adjust the rate of the clock.

This clock was testing well but was too sensitive to external vibrations and had a varying quality of sound and rhythm to the “Tick Tock”. On these older movements the anchor (noted in the pictures) cannot be safely adjusted. The surfaces that interact with the escape wheel need to be polished.

The problem was twofold, the wheel teeth were worn down through the 150 years of use and any error with the teeth had a greater effect on function.

I checked the escape wheel again and there was a barely noticeable length discrepancy with the teeth. To correct this there are several approaches. The first thing of course is to place that arbor/pivots/wheel on the lathe and make sure it spins true (no wobbling). The correction for a bent tooth is straightforward most of the time and I’ll post a not about this in a future post

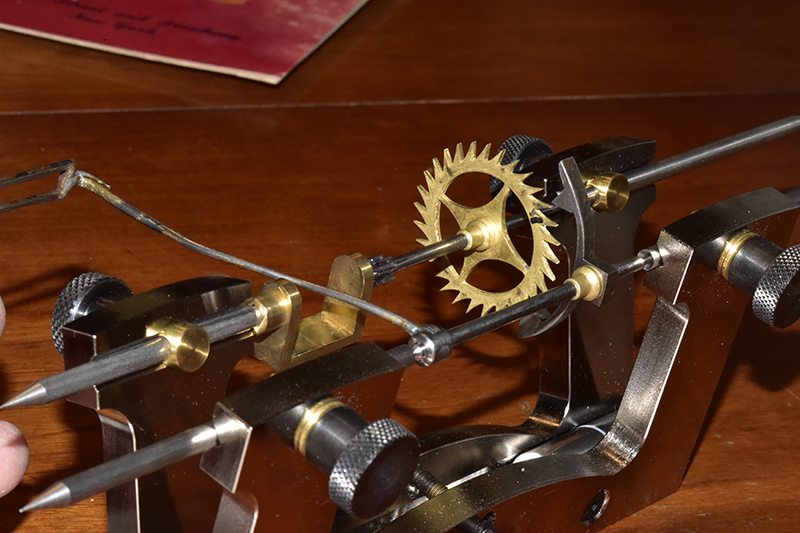

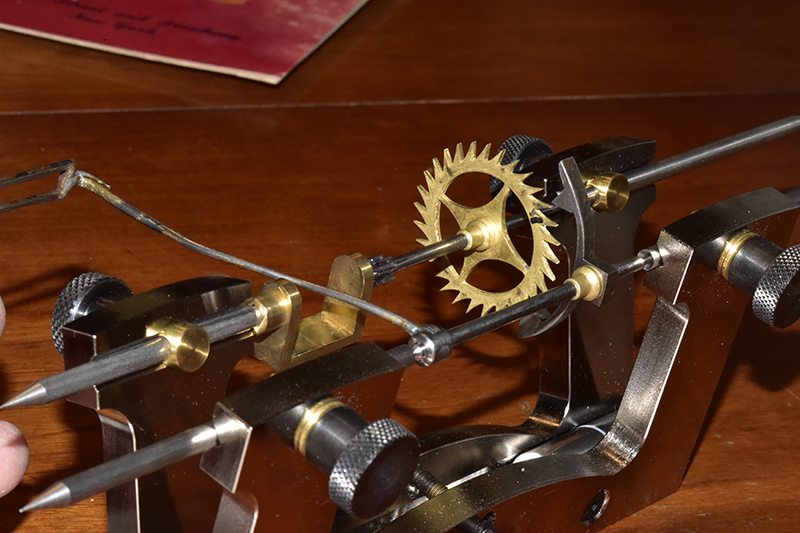

1 There is a topping tool that is specifically made to gently and accurately spin the wheel and allow a grinding so that all the teeth are even in height. After the teeth height is changed the teeth that had the most impact have to be reshaped with a file.

2 One can do this on a lathe but the accuracy is more dependent on the user.

3 The approach I took. Regarding the first approach, I don’t own a Topping tool. They aren’t easy to find. The second is fine for a clock with more forgiveness through adjustments. This clock does not have an anchor that can be brought closer to the wheel or even have the contact surfaces spread or narrowed to fine tune the engagement. Because of this and because I need to preserve the length of the shortest teeth I used the third approach as seen in the pictures.

A Depthing tool is an extremely accurate tool for finding the correct distance that will allow for a proper engagement of one wheel to the pinion of the next. I use this frequently when there has been questionable work done in the past that may have moved bushings (holes) to an incorrect position. The clock may still work but there will be a loss of power.

In this situation, taking advantage of the accuracy of the Depthing tool I use the escape wheel attached normally then I extend a post (dead on parallel). I find the shortest teeth then adjust the position so these teeth do not touch the bar at all (they just miss by an amount thinner than a hair. Then I carefully spin the wheel tooth by tooth and use a mini file to slowly, slowly take down the height until that tooth just misses the bar also. I do this with all the remaining long teeth (about four), then I gently reshape the curve of each tooth and burnish the surface to make sure there is no burr.

The result was fantastic. The sweet sound and even beat of the pendulum action returned and the sensitivity to vibration gone.