Several watches and a unique Bird cage clock slowed down the progress of this story on the Ship Clocks.

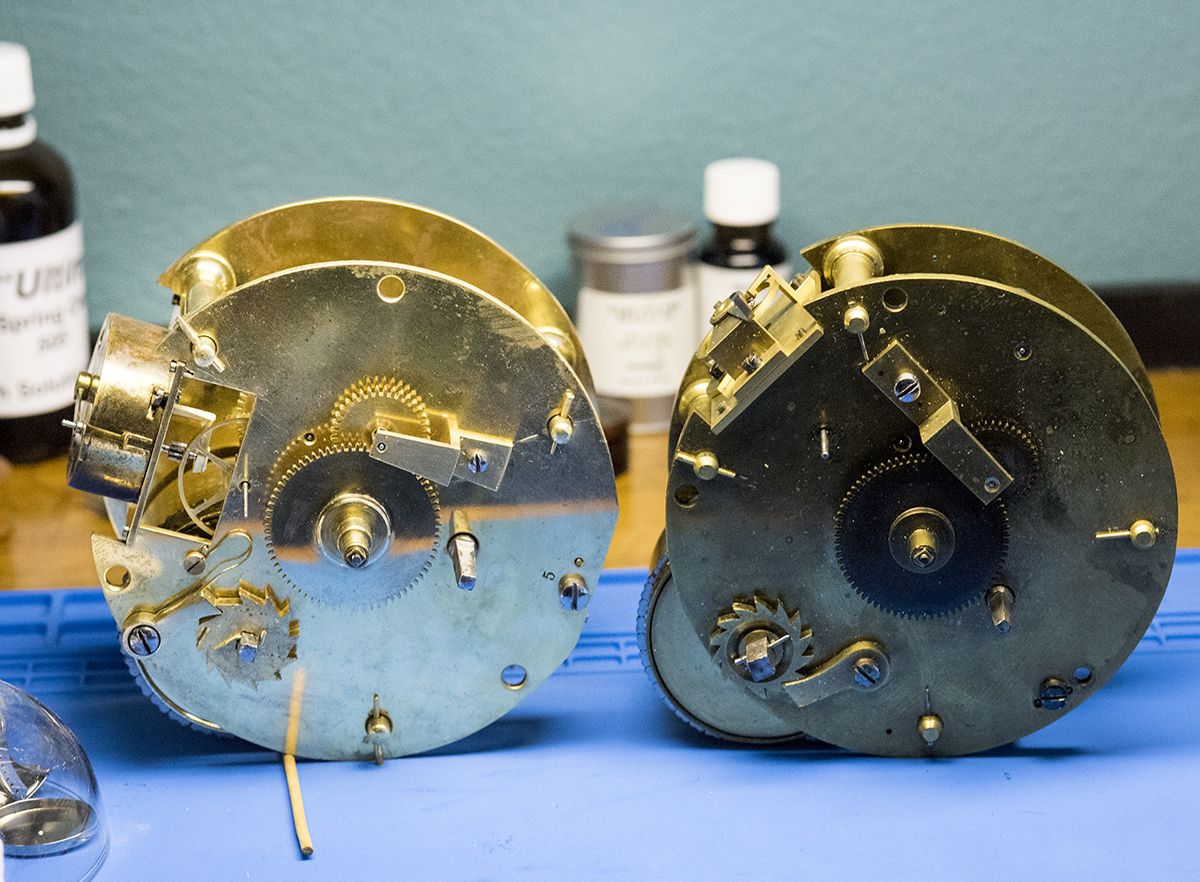

I decided to do one clock at a time since they were so similar. the difference will become evident later when I discuss the smaller Fusee movement.

The First clock is a delight. The bushings needed a gentle touch with the smoothing broach and the pivots needed a small amount of time for polishing. The Fusee chain was quite dirty and had a couple of links that didn’t move as freely as I like. I cleaned the chain, ran it back and forth against a steel large diameter rod (I used to use wood but theoretically small fragment of would could lodge themselves into the chain). After the chain is oiled it is set aside to wait for the full clock assembly

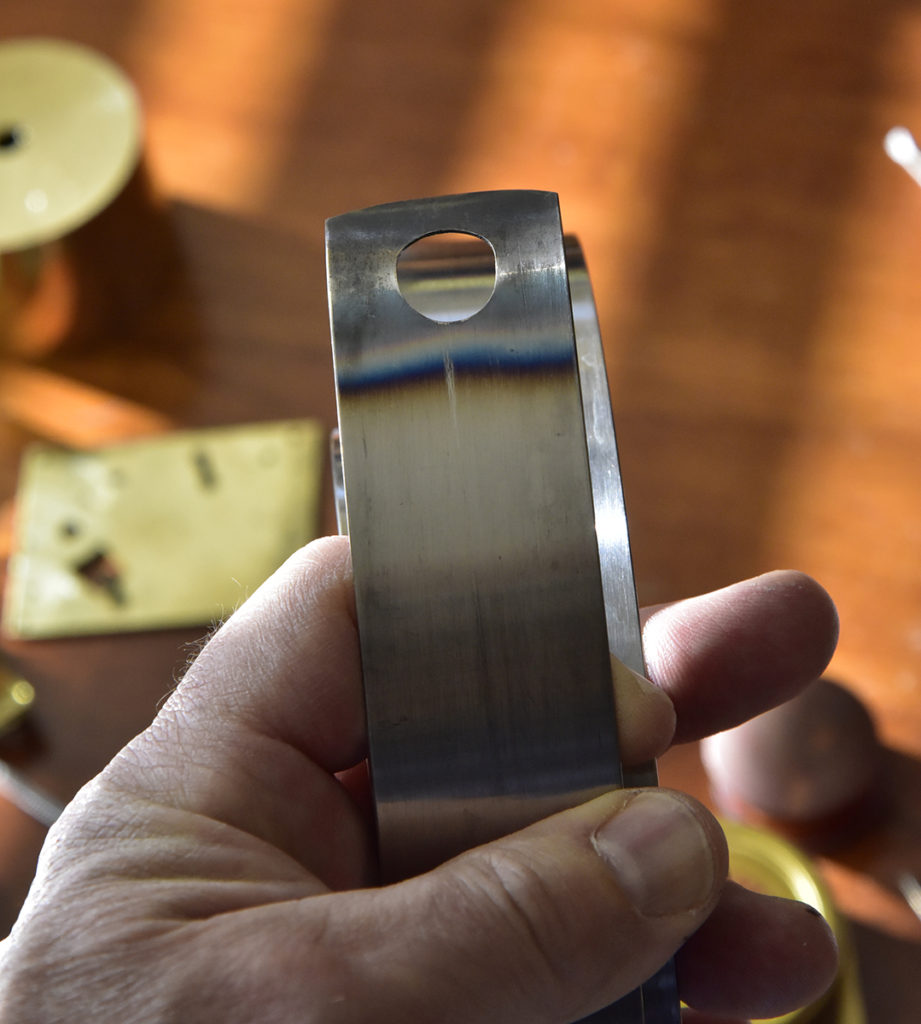

As per the photographs the Fusee slide is used to stop the winding of the chain onto the fusee from the mainspring barrel at a safe point. The ratchet for winding the cone is internal and always dirty with old oil/grease. The click/spring and gear were in good condition. Outside the larger end of the Fusee there are two wheels (gears). The larger one drives the train for power. The thinner smaller diameter wheel is for “Maintaining power”. When the part is wound there is a temporary loss of power that can stop a clock if it is done at the right moment or held too long. There is a spring and a click on the outside of that smaller wheel that hold a small amount of power so there is no let up on the motion for power.

The platform is very large compared to the most common platforms. It is rugged yet nicely manufactured. The jewels and pivots were attended to and the only regret I have is not having the time to swap out the cap jewel screws. There are three Cap jewels that cover the pivot and jewel for the most exposed and delicate parts of the platform escapement. These cap jewels must be removed to clean and inspect this cover. The pivots do touch the caps so just the right amount of oil needs to be applied. Back to the screws, they were all buggered up, unattractive and only barely serviceable. Next time I get to this clock I will pay attention to these screws and make nice polished replacements.

This is a beautiful antique and requires cleaning and gentle polishing but nothing that produces loss of material just for the sake of getting it to look like new. It has some discoloration, some scratches and dings. The point is to make it look decent and to pay most of the attention to all the bearing surfaces that do need to be perfect.

After the movement is getting reassembled I like to wind the chain on the barrel with an approximate distance or spacing that I know suits the Fusee. I connect the chain hook to the fusee then wind the mainspring arbor foe a preset of power. How much you wind it depends on the clock and how long it runs and how well it keeps time. Most clocks need anywhere from a 3/4 turn to 1 1/2 turns. My approach is to see how many clicks it takes to get the escapement moving. If it’s 1-2 then I start with 3/4 turn and so on. This clock ran with one click of a ratchet tooth so I will only power it by 3/4 of a turn. This may need to be adjusted depending on the time keeping.

So…this is a wonderful clock that I really enjoyed. The quality is phenomenal!

I will do just a summary of the second clock and include a brief comparison after that one is cleaned.